In-House Label Printing

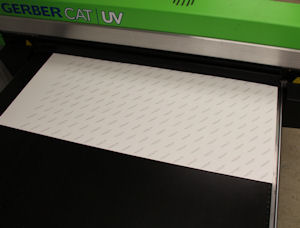

As with many manufacturing companies, TFCO originally relied on outside vendors to provide labels for our products; however, TFCO requires literally thousands of labels in different colors, shapes and sizes. Because of this necessity, we recognized the need to have the in-house ability to print labels for our customers. Our production printer allows us to manufacture the majority of spool labels in-house. This capability, when coupled with our ability to design custom “spool” labels for our products and private labels for our customers, has provided TFCO with an opportunity to better control costs and shorten lead times. This project was so successful that TFCO aquired a different type of printer- capable of producing vivid color labels which satisfied the majority of our square and rectangle “box” label requirements. This second printer is a digital printer which allows us to quickly produce labels for a variety of purposes including short production runs.